Prologue

This document describes the OWL ontology for the Steel Industry case study of the ONTORULE project.

1.1 Coils, defects, phenomena and sampling points

Coils, defects, phenomena and sampling points are at the core of this ontology. Their relationships are not straightfoward. A coil is a physical object which is a metallurgical product. A sampling point is an abstract concept which represents a given location within a coil where some physical parameters are measured. Both defects and phenomena are deviations from the product specifications, which arise at a given product. A key difference between a defect and a phenomenon is that the former is located at a certain sampling point and the latter affects the coil as a whole.

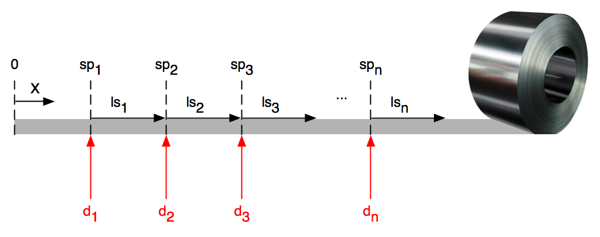

As the coil is sampled at discrete locations along one axis (X), the location of each sampling point (sp) is defined by the length from the start of the coil strip to the sampling point. The distance between a sampling point and the next one is called the length scope (ls) of the first sampling point. Defects (d), if present, are associated to a sampling point. The following diagram illustrates these relationships.

1.2 Physical variables

These are some of the physical variables that are taken into account:

- Yield strength: The yield strength or yield point of a material is defined in engineering and materials science as the stress at which a material begins to deform plastically. Because there is no definite point on the curve where elastic strain ends and plastic strain begins, the yield strength is chosen to be that strength when a definite amount of plastic strain has occurred. For the general engineering structural design, the yield strength is chosen when 0,2 percent plastic strain has taken place. The 0.2 percent yield strength or the 0.2 percent offset yield strength is calculated at 0.2 percent offset from the original cross-sectional area of the sample (s=P/A).

- Elongation: Elongation is a measurement of the ductility of the steel. When a material is tested for tensile strength it elongates a certain amount before fracture takes place. The two pieces are placed together and the amount of extension is measured against marks made before starting the test and is expressed as a percentage of the original gauge length.

- Temperature: In the context of this ontology, this variable refers to the temperature measured in the steel strip at the end of the heating (measured in ºC).

1.3 Product type

Different kinds of steel are usually identified in the industry by their steel grade, which is usually codified as an alphanumeric code. In the context of this ontology, however, a coarser classification is used, which involves a hierarchy of product types. Product types are identified by shorter alphanumeric codes.

Appendix

A. References

- PROD-DEF

- ArcelorMittal Product Catalogue - EU edition 2008 (cf. Product Definition)

- ORDER-ASS

- ArcelorMittal internal report on 'Order assignment at Galvanisation Line'

B. Changes in this version

- 31/05/2010

- Initial version of the specification

C. Acknowledgements

This work is part of the ONTORULE project (ONTOlogies meet business RULEs), a large-scale integrating project (IP) partially funded by the European Union's 7th Framework Programmen under the Information and Communication Technologies (ICT) Call 3 (ICT-231875).

The consortium of the project is composed by the following partners:

- Audi

- ArcelorMittal

- Free University of Bolzano

- Fundación CTIC

- ILOG/IBM

- ontoprise

- Université Paris 13

- PNA

- TU WIEN

For futher information, please visit the official webpage of the project: http://ontorule-project.eu/

The authors want to explicitely acknowledge the contributions made by François Lévy (Universite Paris 13) and Antonia Schwichtenberg (ontoprise).