Ontology of the Steel Industry Case Study

Final version — 31 May 2010

- This version:

- http://ontorule-project.eu/resources/steel

- Latest version:

- http://ontorule-project.eu/resources/steel

- Last Update:

- 31 May 2010

- Editors:

- Luis Polo, Fundación CTIC

- Diego Díaz, ArcelorMittal

- Authors:

- Pablo Valledor, ArcelorMittal

- Diego Berrueta, Fundación CTIC

- Emilio Rubiera, Fundación CTIC

- Contributors:

- See acknowledgements

© ONTORULE Project, all rights reserved.

Abstract

This document describes the OWL ontology for the Steel Industry case study of the ONTORULE project.

This document contains the reference documentation for each entity (class, property, instance) of the ontology. It also includes some companion text with pertinent explanations about the domain concepts.

Status of this Document

This is the current version of the Steel Industry Case Study ontology.

Table of Contents

Appendixes

1. Introduction

This document describes the OWL ontology for the Steel Industry case study of the ONTORULE project.

1.1 Coils, defects, phenomena and sampling points

Coils, defects, phenomena and sampling points are at the core of this ontology. Their relationships are not straightfoward. A coil is a physical object which is a metallurgical product. A sampling point is an abstract concept which represents a given location within a coil where some physical parameters are measured. Both defects and phenomena are deviations from the product specifications, which arise at a given product. A key difference between a defect and a phenomenon is that the former is located at a certain sampling point and the latter affects the coil as a whole.

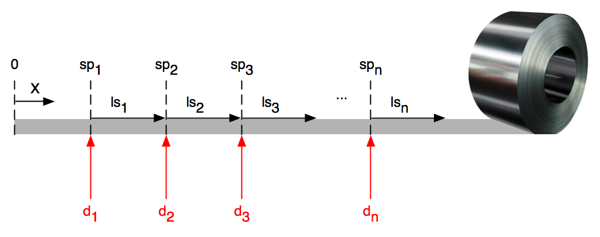

As the coil is sampled at discrete locations along one axis (X), the location of each sampling point (sp) is defined by the length from the start of the coil strip to the sampling point. The distance between a sampling point and the next one is called the length scope (ls) of the first sampling point. Defects (d), if present, are associated to a sampling point. The following diagram illustrates these relationships.

1.2 Physical variables

These are some of the physical variables that are taken into account:

- Yield strength: The yield strength or yield point of a material is defined in engineering and materials science as the stress at which a material begins to deform plastically. Because there is no definite point on the curve where elastic strain ends and plastic strain begins, the yield strength is chosen to be that strength when a definite amount of plastic strain has occurred. For the general engineering structural design, the yield strength is chosen when 0,2 percent plastic strain has taken place. The 0.2 percent yield strength or the 0.2 percent offset yield strength is calculated at 0.2 percent offset from the original cross-sectional area of the sample (s=P/A).

- Elongation: Elongation is a measurement of the ductility of the steel. When a material is tested for tensile strength it elongates a certain amount before fracture takes place. The two pieces are placed together and the amount of extension is measured against marks made before starting the test and is expressed as a percentage of the original gauge length.

- Temperature: In the context of this ontology, this variable refers to the temperature measured in the steel strip at the end of the heating (measured in ºC).

1.3 Product type

Different kinds of steel are usually identified in the industry by their steel grade, which is usually codified as an alphanumeric code. In the context of this ontology, however, a coarser classification is used, which involves a hierarchy of product types. Product types are identified by shorter alphanumeric codes.

2. Ontology at a glance

An alphabetical index of the ontology terms, by class (concepts) and by property (relationships, attributes), is given below. All the terms are hyperlinked to their detailed description for quick reference.

Classes: Action, Clinching, Coil, Defect, DualPhase, HSLA, InterstitialFree, MechanicalDefect, MechanicalPhenomenon, Order, ParameterDefect, Phenomenon, ProductType, Rephosphorised, SamplingPoint, SkinPassElongationDefect, SkinPassElongationPhenomenon, SurfaceAspectDefect, SurfaceAspectPhenomenon, TemperatureDefect, TemperaturePhenomenon, YieldStrengthDefect, YieldStrengthPhenomenon,

Properties: action, avgFlattenerElongation, avgSkinPassElongation, avgTemperature, coilIdentifier, coilProperty, derivesFrom, flattenerElongation, hasPhenomenon, hasSamplingPoint, inCoil, lengthScope, location, locationOf, order, phenomenonOf, position, productTypeCode, samplingPointProperty, skinPassElongation, skinPassElongationMax, skinPassElongationMin, steelGrade, targetParameter, temperature, temperatureMax, temperatureMin, thicknessTarget, weightMax, weightMin, widthTarget, yieldStrength, yieldStrengthMax, yieldStrengthMin, zincThicknessTarget,

Instances: A200, B102, B105, C114, C116, C119, D012, D071, evaluation, K012, keepAssignment, repair, scrap,

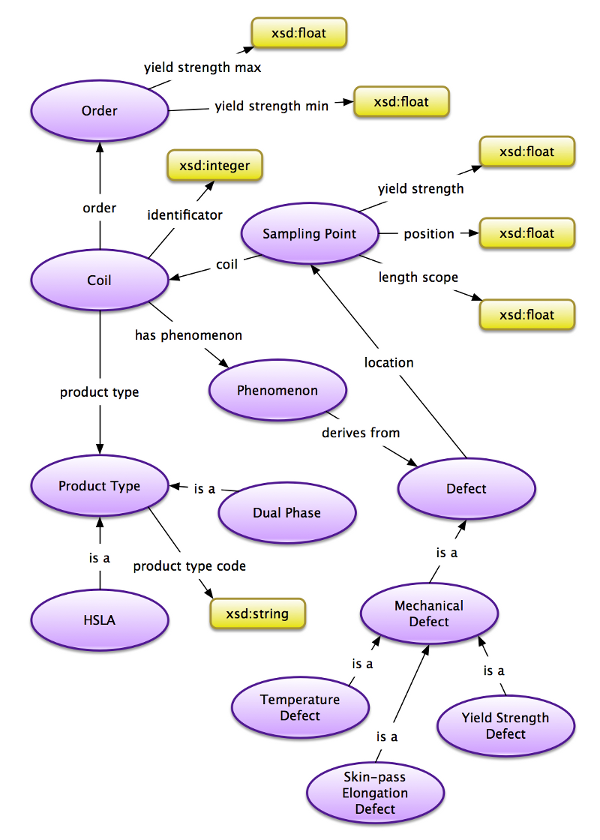

The following diagram illustrates some of the concepts and properties of the Steel Case Study ontology.

3. Cross-reference of classes and properties

Class: steel:Action

URI: http://ontorule-project.eu/resources/steel#Action

Action - This category comprises the actions to be done with the product after the system has completed its evaluation

- in-range-of:

- steel:action

Class: steel:Clinching

URI: http://ontorule-project.eu/resources/steel#Clinching

Clinching - Clinching steels are those obtained by a non-continuous method of joining whereby the points of joinage are produced by punching two or more steel sheets together simultaneously by means of a punch and die.

- sub-class-of:

- steel:ProductType

Class: steel:Coil

URI: http://ontorule-project.eu/resources/steel#Coil

Coil - A coil is a physical object which is the metallurgical product to be analysed during the process.

Class: steel:Defect

URI: http://ontorule-project.eu/resources/steel#Defect

An imperfection or defect detected in the coil. -

- in-domain-of:

- steel:location

- in-range-of:

- steel:derivesFrom

- steel:locationOf

Class: steel:DualPhase

URI: http://ontorule-project.eu/resources/steel#DualPhase

Dual-phase steel - Dual-phase steel (DPA) is a high-strength steel that has a ferrite and martensitic microstructure. DPA starts as a low or medium carbon steel and is quenched from a temperature above A1 but below A3 on a continuous cooling transformation diagram. This results in a microstructure consisting of a soft ferrite matrix containing islands of martensite as the secondary phase (martensite increases the tensile strength). It features advantages such as low yield strength;low yield to tensile strength ratio (yield strength / tensile strength = 0.5); high initial strain hardening rates; good uniform elongation; high strain rate sensitivity (the faster it is crushed the more energy it absorbs); and good fatigue resistance.

- sub-class-of:

- steel:ProductType

Class: steel:HSLA

URI: http://ontorule-project.eu/resources/steel#HSLA

High-strength low-alloy steel - High-strength low-alloy (HSLA) steel is a type of alloy steel that provides better mechanical properties or greater resistance to corrosion than carbon steel. HSLA steels vary from other steels in that they aren't made to meet a specific chemical composition, but rather to specific mechanical properties. They have a carbon content between 0.05–0.25% to retain formability and weldability.

- sub-class-of:

- steel:ProductType

Class: steel:InterstitialFree

URI: http://ontorule-project.eu/resources/steel#InterstitialFree

Intertitial free metallurgy steel - Steels designed to provide an excellent combination of drawability and mechanical strength based on their specific interstitial free (IF) metallurgy. These steels are hardened by adding manganese, silicon and phosphorous in solid solution to the ferrite. The metallurgy of IF steels optimizes their drawability.

- sub-class-of:

- steel:ProductType

Class: steel:MechanicalDefect

URI: http://ontorule-project.eu/resources/steel#MechanicalDefect

Mechanical defect - A defect having to do with the mechanical process.

- sub-class-of:

- steel:Defect

Class: steel:MechanicalPhenomenon

URI: http://ontorule-project.eu/resources/steel#MechanicalPhenomenon

Mechanical phenomenon - An effect detected in the coil related to the mechanical process.

- sub-class-of:

- steel:Phenomenon

Class: steel:Order

URI: http://ontorule-project.eu/resources/steel#Order

Order - An order defines the target specifications of the product. The order also specifies the tolerance allowed with respect to the target parameters.

- in-domain-of:

- steel:targetParameter

- steel:widthTarget

- steel:yieldStrengthMax

- steel:yieldStrengthMin

- in-range-of:

- steel:order

Class: steel:ParameterDefect

URI: http://ontorule-project.eu/resources/steel#ParameterDefect

Parameter defect - It is a defect having to do with a deviation of the measured skin-pass elongation, flattener elongation or temperature from the specified values.

- sub-class-of:

- steel:MechanicalDefect

Class: steel:Phenomenon

URI: http://ontorule-project.eu/resources/steel#Phenomenon

Phenomenon - An effect detected in the coil, based on the identified defects along the coil sampling points.

- in-domain-of:

- steel:derivesFrom

- steel:phenomenonOf

- in-range-of:

- steel:hasPhenomenon

Class: steel:ProductType

URI: http://ontorule-project.eu/resources/steel#ProductType

Product type - The type identifies the kind of steel, defined by a set of physical and chemical properties

- in-domain-of:

- steel:productTypeCode

- in-range-of:

- steel:steelGrade

Class: steel:Rephosphorised

URI: http://ontorule-project.eu/resources/steel#Rephosphorised

Rephosphorised steel - It is a kind of steel that contains phosphorus as its main alloying agent.

- sub-class-of:

- steel:ProductType

Class: steel:SamplingPoint

URI: http://ontorule-project.eu/resources/steel#SamplingPoint

Sampling point - A sampling point is an abstract concept which represents a given location within a coil where some physical parameters are measured.

Class: steel:SkinPassElongationDefect

URI: http://ontorule-project.eu/resources/steel#SkinPassElongationDefect

Skin-pass elongation defect - A skin-pass elongation defect has to do with any deviation of the measured skin-pass elongation from the requirements for the product.

- sub-class-of:

- steel:MechanicalDefect

Class: steel:SkinPassElongationPhenomenon

URI: http://ontorule-project.eu/resources/steel#SkinPassElongationPhenomenon

Skin-pass elongation phenomenon - An effect detected in the coil related to the skin-pass elongation.

- sub-class-of:

- steel:MechanicalPhenomenon

Class: steel:SurfaceAspectDefect

URI: http://ontorule-project.eu/resources/steel#SurfaceAspectDefect

Surface aspect defect - A defect found in the surface of the coil.

- sub-class-of:

- steel:Defect

Class: steel:SurfaceAspectPhenomenon

URI: http://ontorule-project.eu/resources/steel#SurfaceAspectPhenomenon

Surface aspect phenomenon - An effect detected in the coil specifically on the surface of the product.

- sub-class-of:

- steel:Phenomenon

Class: steel:TemperatureDefect

URI: http://ontorule-project.eu/resources/steel#TemperatureDefect

Temperature defect - It is a defect having to do with temperature issues. At the exit of the furnace it is necessary to check the temperature ranges of the steel strip, depending on the maximum and minimum end of heating temperature set by the order (measured in ºC) and the steel grade.

- sub-class-of:

- steel:MechanicalDefect

Class: steel:TemperaturePhenomenon

URI: http://ontorule-project.eu/resources/steel#TemperaturePhenomenon

Temperature phenomenon - An effect detected in the coil related to the temperature.

- sub-class-of:

- steel:MechanicalPhenomenon

Class: steel:YieldStrengthDefect

URI: http://ontorule-project.eu/resources/steel#YieldStrengthDefect

Yield strength defect - It is a mechanical defect having to do with the target yield strength. A defect of this category is identified if the yield strength is outside of the target range at any point.

- sub-class-of:

- steel:MechanicalDefect

Class: steel:YieldStrengthPhenomenon

URI: http://ontorule-project.eu/resources/steel#YieldStrengthPhenomenon

Yield strength phenomenon - An effect detected in the coil related to the yield strength.

- sub-class-of:

- steel:MechanicalPhenomenon

Property: steel:action

URI: http://ontorule-project.eu/resources/steel#action

action - This is the final assignment of a coil to an order (a customer)

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Coil

- Range:

- steel:Action

Property: steel:avgFlattenerElongation

URI: http://ontorule-project.eu/resources/steel#avgFlattenerElongation

average flattener elongation -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:coilProperty

- Domain:

- steel:Coil

Property: steel:avgSkinPassElongation

URI: http://ontorule-project.eu/resources/steel#avgSkinPassElongation

average skin-pass elongation -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:coilProperty

- Domain:

- steel:Coil

Property: steel:avgTemperature

URI: http://ontorule-project.eu/resources/steel#avgTemperature

average temperature -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:coilProperty

- Domain:

- steel:Coil

Property: steel:coilIdentifier

URI: http://ontorule-project.eu/resources/steel#coilIdentifier

coil identifier - Unique identifier of the product.

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:coilProperty

- Domain:

- steel:Coil

- Range:

- xsd:integer

Property: steel:coilProperty

URI: http://ontorule-project.eu/resources/steel#coilProperty

coil property -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- owl:topDataProperty

- Domain:

- steel:Coil

Property: steel:derivesFrom

URI: http://ontorule-project.eu/resources/steel#derivesFrom

derives from - A given phenomenon derives from a set of defects.

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Phenomenon

- Range:

- steel:Defect

Property: steel:flattenerElongation

URI: http://ontorule-project.eu/resources/steel#flattenerElongation

flattener elongation -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:samplingPointProperty

- Domain:

- steel:SamplingPoint

Property: steel:hasPhenomenon

URI: http://ontorule-project.eu/resources/steel#hasPhenomenon

has phenomenon -

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Coil

- Range:

- steel:Phenomenon

Property: steel:hasSamplingPoint

URI: http://ontorule-project.eu/resources/steel#hasSamplingPoint

has sampling point -

- Inverse:

- steel:inCoil

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Coil

- Range:

- steel:SamplingPoint

Property: steel:inCoil

URI: http://ontorule-project.eu/resources/steel#inCoil

in coil - This property links sampling points, used by the system to measure some physical parameters such as the yield strength, to the product (a given coil).

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:SamplingPoint

- Range:

- steel:Coil

Property: steel:lengthScope

URI: http://ontorule-project.eu/resources/steel#lengthScope

length scope - Length of the coil in which the sampling applies. It is associated to a single coil sampling point.

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:samplingPointProperty

- Domain:

- steel:SamplingPoint

- Range:

- xsd:float

Property: steel:location

URI: http://ontorule-project.eu/resources/steel#location

location - A defect is detected comparing coil data with order specifications in sampling points. Thus a defect is relative to a position in the coil.

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Defect

- Range:

- steel:SamplingPoint

Property: steel:locationOf

URI: http://ontorule-project.eu/resources/steel#locationOf

location of -

- Inverse:

- steel:location

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:SamplingPoint

- Range:

- steel:Defect

Property: steel:order

URI: http://ontorule-project.eu/resources/steel#order

order - This is the initial assignment of a coil to an order (a customer). It will define the production goal to be validated by the rule system.

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Coil

- Range:

- steel:Order

Property: steel:phenomenonOf

URI: http://ontorule-project.eu/resources/steel#phenomenonOf

phenomenon of -

- Inverse:

- steel:hasPhenomenon

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Phenomenon

- Range:

- steel:Coil

Property: steel:position

URI: http://ontorule-project.eu/resources/steel#position

position - Position of the coil where a sampling is performed. There is a sampling point each 10 meters from the head to the tail of the coil, so the position indicates the distance in meters from the head to a given sampling point.

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:samplingPointProperty

- Domain:

- steel:SamplingPoint

- Range:

- xsd:float

Property: steel:productTypeCode

URI: http://ontorule-project.eu/resources/steel#productTypeCode

product type code -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- owl:topDataProperty

- Domain:

- steel:ProductType

Property: steel:samplingPointProperty

URI: http://ontorule-project.eu/resources/steel#samplingPointProperty

sampling point property -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- owl:topDataProperty

- Domain:

- steel:SamplingPoint

Property: steel:skinPassElongation

URI: http://ontorule-project.eu/resources/steel#skinPassElongation

skin-pass elongation -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:samplingPointProperty

- Domain:

- steel:SamplingPoint

Property: steel:skinPassElongationMax

URI: http://ontorule-project.eu/resources/steel#skinPassElongationMax

skin-pass elongation maximum -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Property: steel:skinPassElongationMin

URI: http://ontorule-project.eu/resources/steel#skinPassElongationMin

skin-pass elongation minimum -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Property: steel:steelGrade

URI: http://ontorule-project.eu/resources/steel#steelGrade

steel grade -

- OWL Type:

- ObjectProperty

- sub-property-of:

- owl:topObjectProperty

- Domain:

- steel:Coil

- Range:

- steel:ProductType

Property: steel:targetParameter

URI: http://ontorule-project.eu/resources/steel#targetParameter

target parameter -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- owl:topDataProperty

- Domain:

- steel:Order

Property: steel:temperature

URI: http://ontorule-project.eu/resources/steel#temperature

temperature -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:samplingPointProperty

- Domain:

- steel:SamplingPoint

Property: steel:temperatureMax

URI: http://ontorule-project.eu/resources/steel#temperatureMax

temperature maximum -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Property: steel:temperatureMin

URI: http://ontorule-project.eu/resources/steel#temperatureMin

temperature minimum -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Property: steel:thicknessTarget

URI: http://ontorule-project.eu/resources/steel#thicknessTarget

thickness target -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Property: steel:weightMax

URI: http://ontorule-project.eu/resources/steel#weightMax

weight maximum -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Property: steel:weightMin

URI: http://ontorule-project.eu/resources/steel#weightMin

weight minimum -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Property: steel:widthTarget

URI: http://ontorule-project.eu/resources/steel#widthTarget

width target -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

- Domain:

- steel:Order

Property: steel:yieldStrength

URI: http://ontorule-project.eu/resources/steel#yieldStrength

yield strength - This parameter is calculated in every sampling point along the coil. So the yieldStrength is associated with a given sampling point to allow the comparison with the yieldStrength value of the target specified in the order. Deviations from the target imply a defect in the coil.

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:samplingPointProperty

- Domain:

- steel:SamplingPoint

- Range:

- xsd:float

Property: steel:yieldStrengthMax

URI: http://ontorule-project.eu/resources/steel#yieldStrengthMax

yield strength upper tolerance -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

- Domain:

- steel:Order

- Range:

- xsd:float

Property: steel:yieldStrengthMin

URI: http://ontorule-project.eu/resources/steel#yieldStrengthMin

yield strength lower tolerance -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

- Domain:

- steel:Order

- Range:

- xsd:float

Property: steel:zincThicknessTarget

URI: http://ontorule-project.eu/resources/steel#zincThicknessTarget

zinc thickness target -

- OWL Type:

- DatatypeProperty

- sub-property-of:

- steel:targetParameter

Instance: steel:A200

URI: http://ontorule-project.eu/resources/steel#A200

A200 -

- RDF Type:

- steel:DualPhase

- owl:Thing

Instance: steel:B102

URI: http://ontorule-project.eu/resources/steel#B102

B102 -

- RDF Type:

- steel:InterstitialFree

- owl:Thing

Instance: steel:B105

URI: http://ontorule-project.eu/resources/steel#B105

B105 -

- RDF Type:

- steel:InterstitialFree

- owl:Thing

Instance: steel:C114

URI: http://ontorule-project.eu/resources/steel#C114

C114 -

- RDF Type:

- steel:Rephosphorised

- owl:Thing

Instance: steel:C116

URI: http://ontorule-project.eu/resources/steel#C116

C116 -

- RDF Type:

- owl:Thing

- steel:Rephosphorised

Instance: steel:C119

URI: http://ontorule-project.eu/resources/steel#C119

C119 -

- RDF Type:

- owl:Thing

- steel:Rephosphorised

Instance: steel:D012

URI: http://ontorule-project.eu/resources/steel#D012

D012 -

- RDF Type:

- owl:Thing

- steel:HSLA

Instance: steel:D071

URI: http://ontorule-project.eu/resources/steel#D071

D071 -

- RDF Type:

- owl:Thing

- steel:HSLA

Instance: steel:evaluation

URI: http://ontorule-project.eu/resources/steel#evaluation

evaluation - The coil is sent to experts when it is not clear whether it meets order requirements

- RDF Type:

- owl:Thing

- steel:Action

Instance: steel:K012

URI: http://ontorule-project.eu/resources/steel#K012

K012 -

- RDF Type:

- owl:Thing

- steel:Clinching

Instance: steel:keepAssignment

URI: http://ontorule-project.eu/resources/steel#keepAssignment

Keep assignment -

- RDF Type:

- steel:Action

- owl:Thing

Instance: steel:repair

URI: http://ontorule-project.eu/resources/steel#repair

repair - When the quality of coil is low but it could be repaired, it is sent again to the production line.

- RDF Type:

- owl:Thing

- steel:Action

Instance: steel:scrap

URI: http://ontorule-project.eu/resources/steel#scrap

scrap - When the quality of the coil is very low, it is sent to scrap

- RDF Type:

- steel:Action

- owl:Thing

A. References

- PROD-DEF

- ArcelorMittal Product Catalogue - EU edition 2008 (cf. Product Definition)

- ORDER-ASS

- ArcelorMittal internal report on 'Order assignment at Galvanisation Line'

B. Changes in this version

- 31/05/2010

- Initial version of the specification

C. Acknowledgements

This work is part of the ONTORULE project (ONTOlogies meet business RULEs), a large-scale integrating project (IP) partially funded by the European Union's 7th Framework Programmen under the Information and Communication Technologies (ICT) Call 3 (ICT-231875).

The consortium of the project is composed by the following partners:

- Audi

- ArcelorMittal

- Free University of Bolzano

- Fundación CTIC

- ILOG/IBM

- ontoprise

- Université Paris 13

- PNA

- TU WIEN

For futher information, please visit the official webpage of the project: http://ontorule-project.eu/

The authors want to explicitely acknowledge the contributions made by François Lévy (Universite Paris 13) and Antonia Schwichtenberg (ontoprise).